OUR SISTER COMPANY ULTRATEC INNOVATIVE TECHNOLOGY

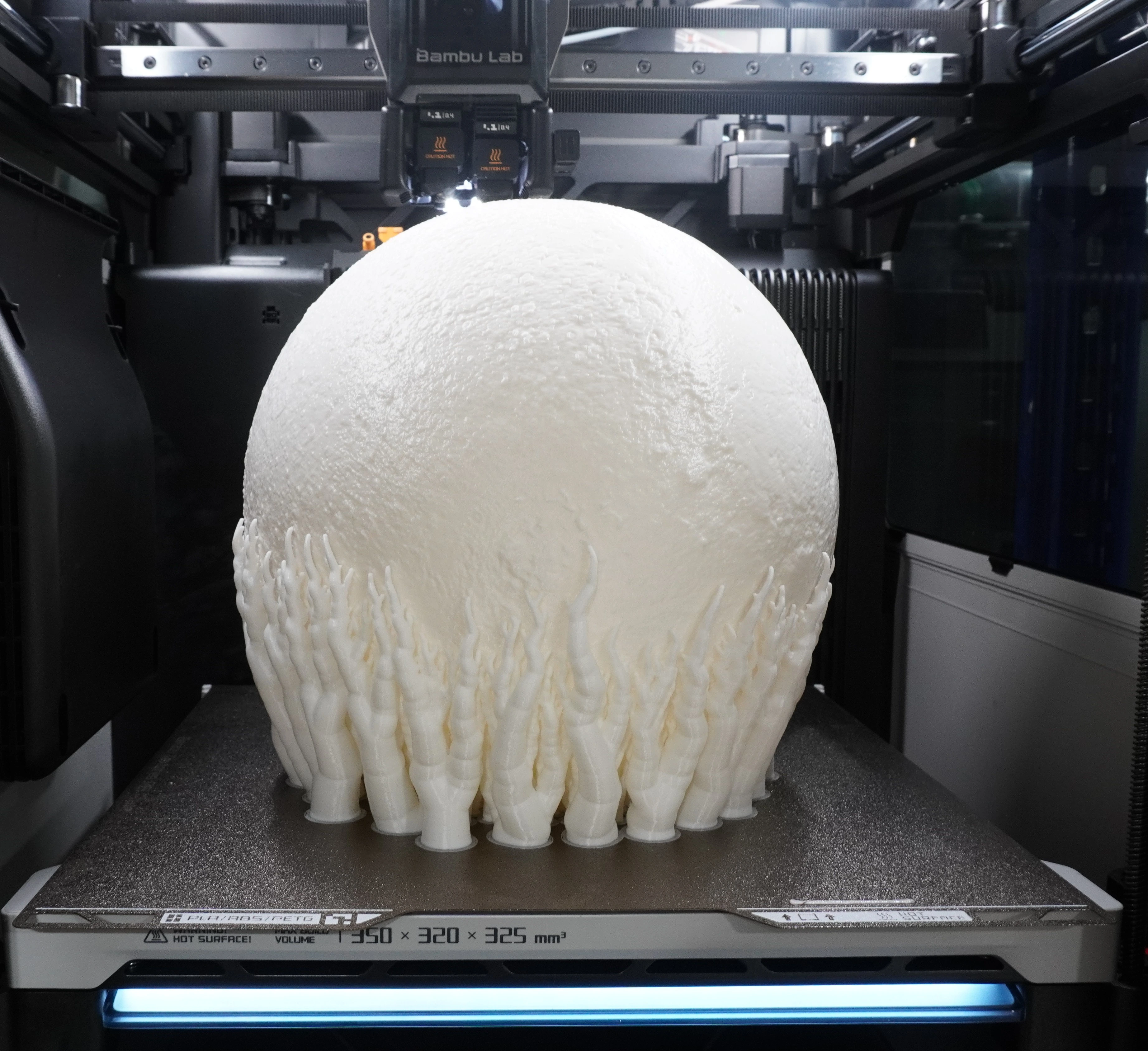

Looking for the best 3D printing and engineering services in the UAE, Saudi Arabia and Worldwide? With over 10 years of expertise, we specialize in precision engineering, advanced 3D scanning, and high-performance 3D printing to bring your ideas to life. From Color Jet 3D printing to laser engraving, signage, and automotive 3D printing, we provide flawless finishes with expert painting and detailing.

From concept to creation — discover how our advanced technology brings your ideas to life.

We transform visionary ideas into tangible results with next-generation manufacturing technologies.

Read more

Creating forward-thinking products that matter to today’s consumers.

Read more

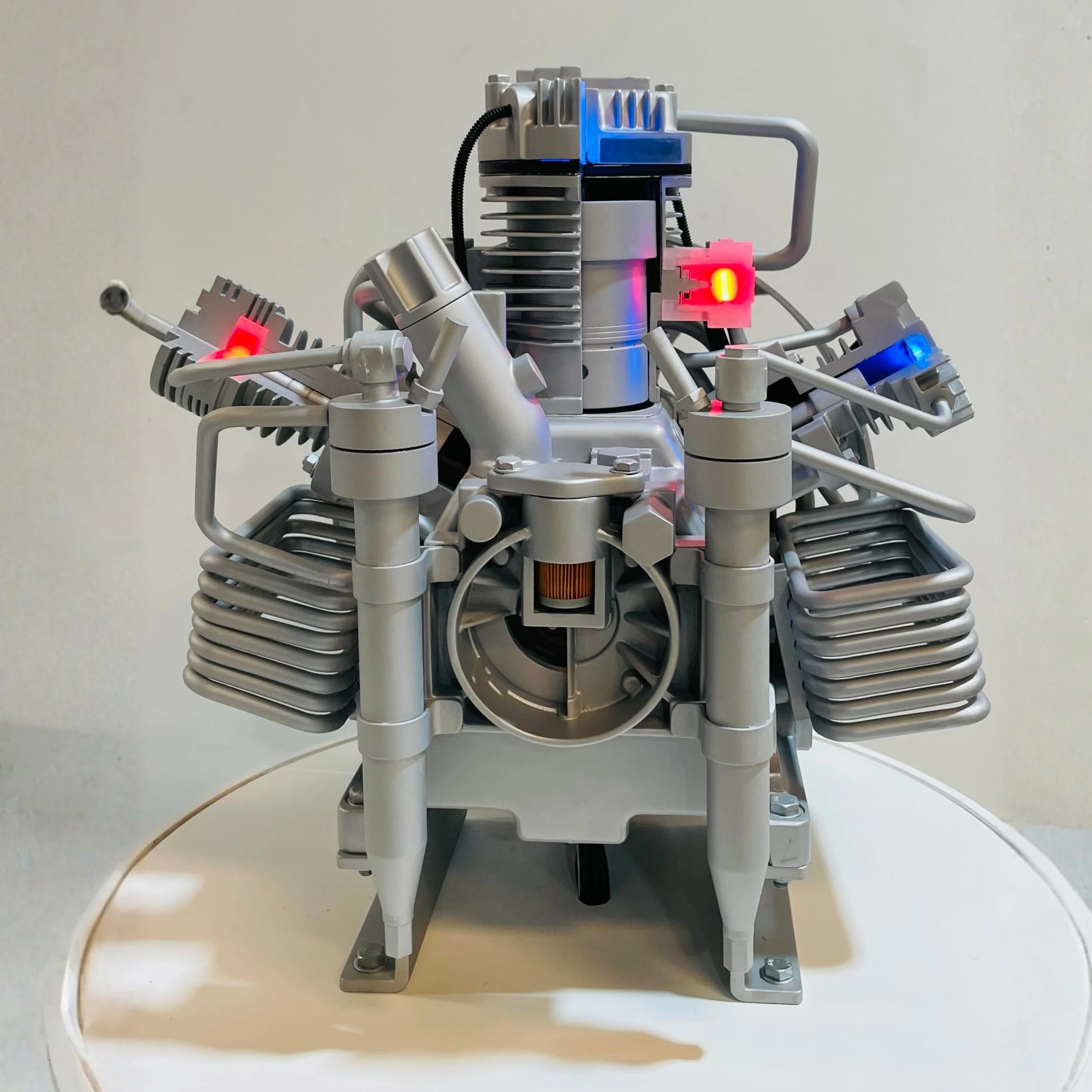

We bring 3D-printed objects to life through seamless mechatronics integration.

Read more

Our paint and processing techniques ensure precise product designs and paintings.

Read more

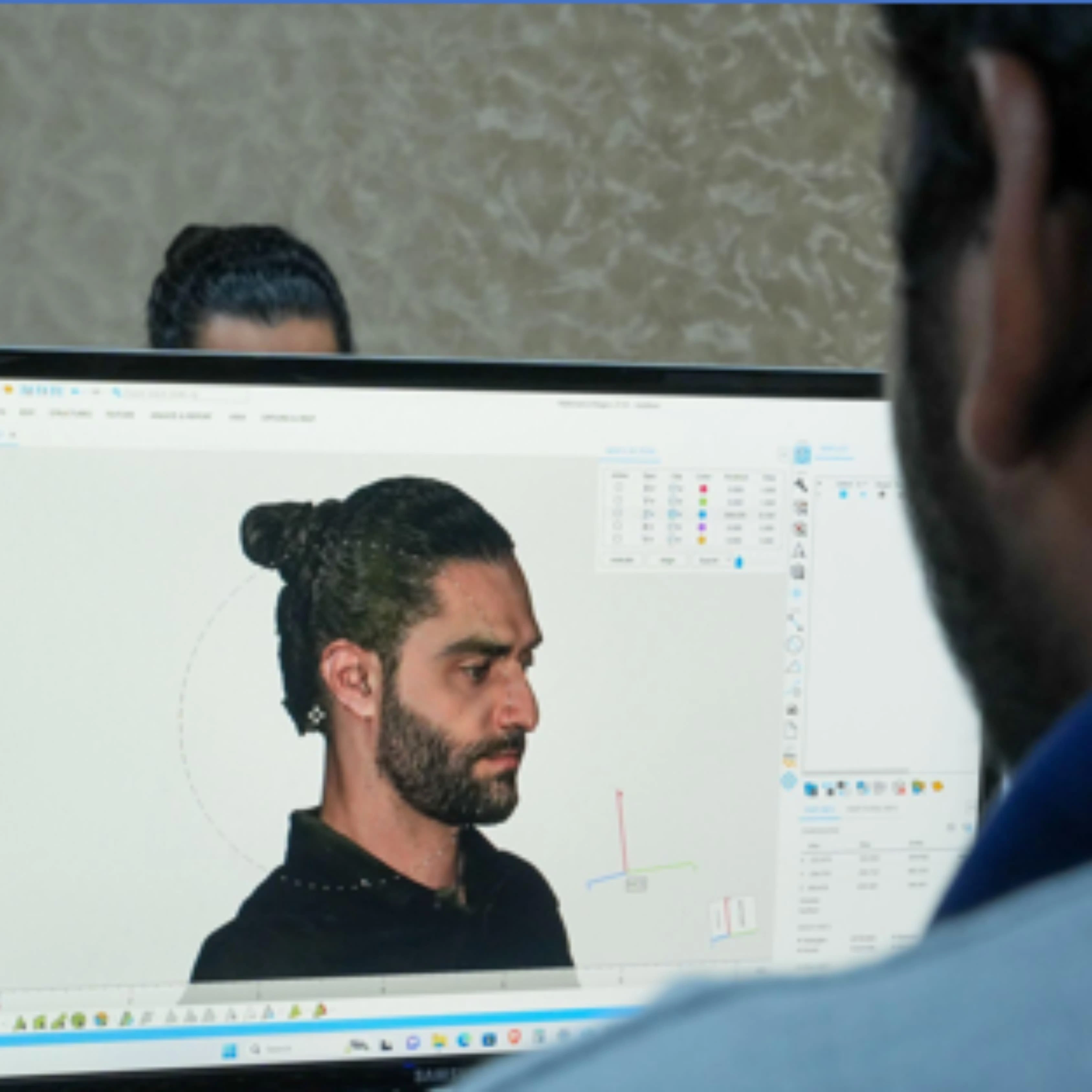

Ultratec offers complete design and scanning solutions from concept to production.

Read more

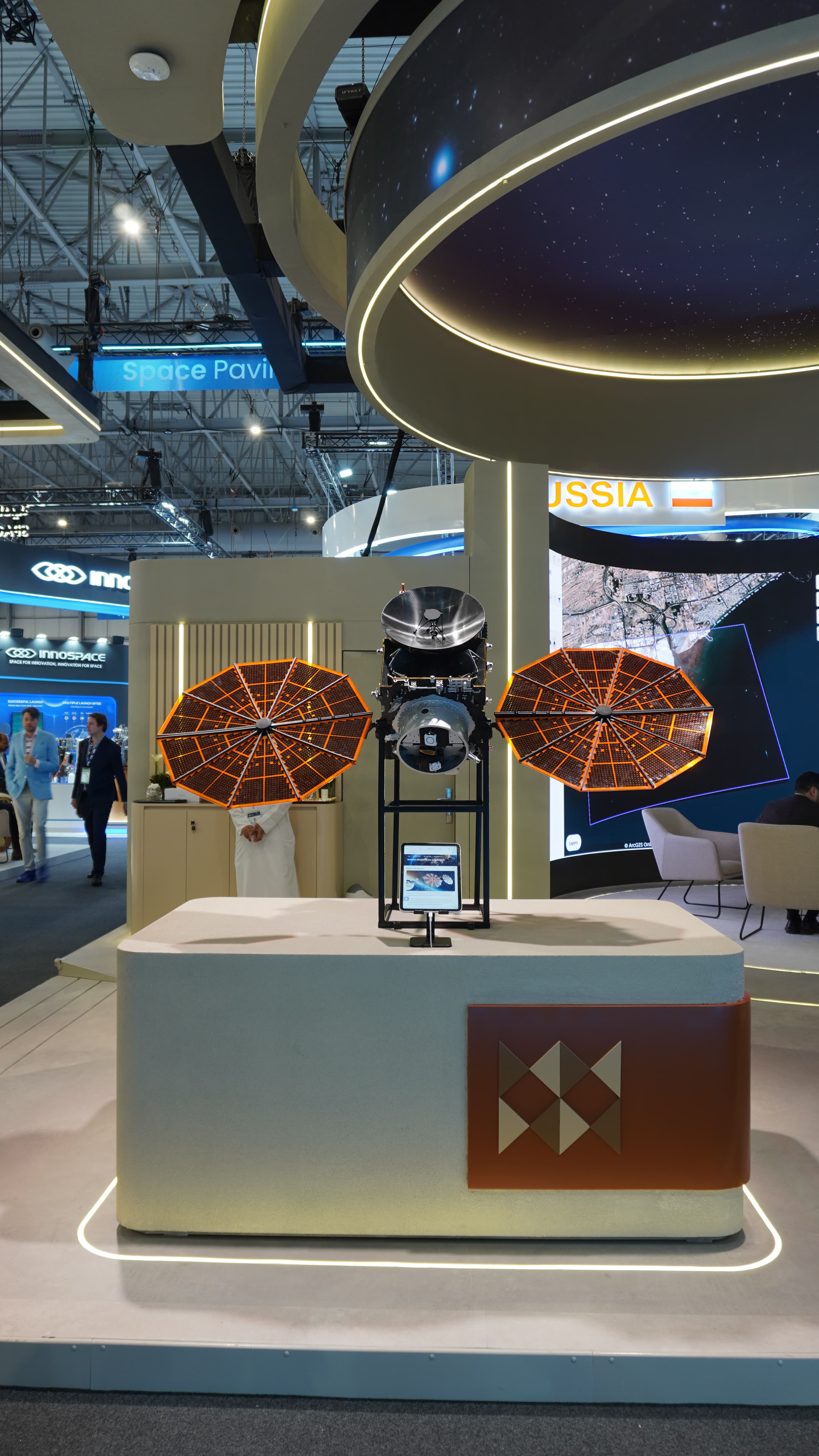

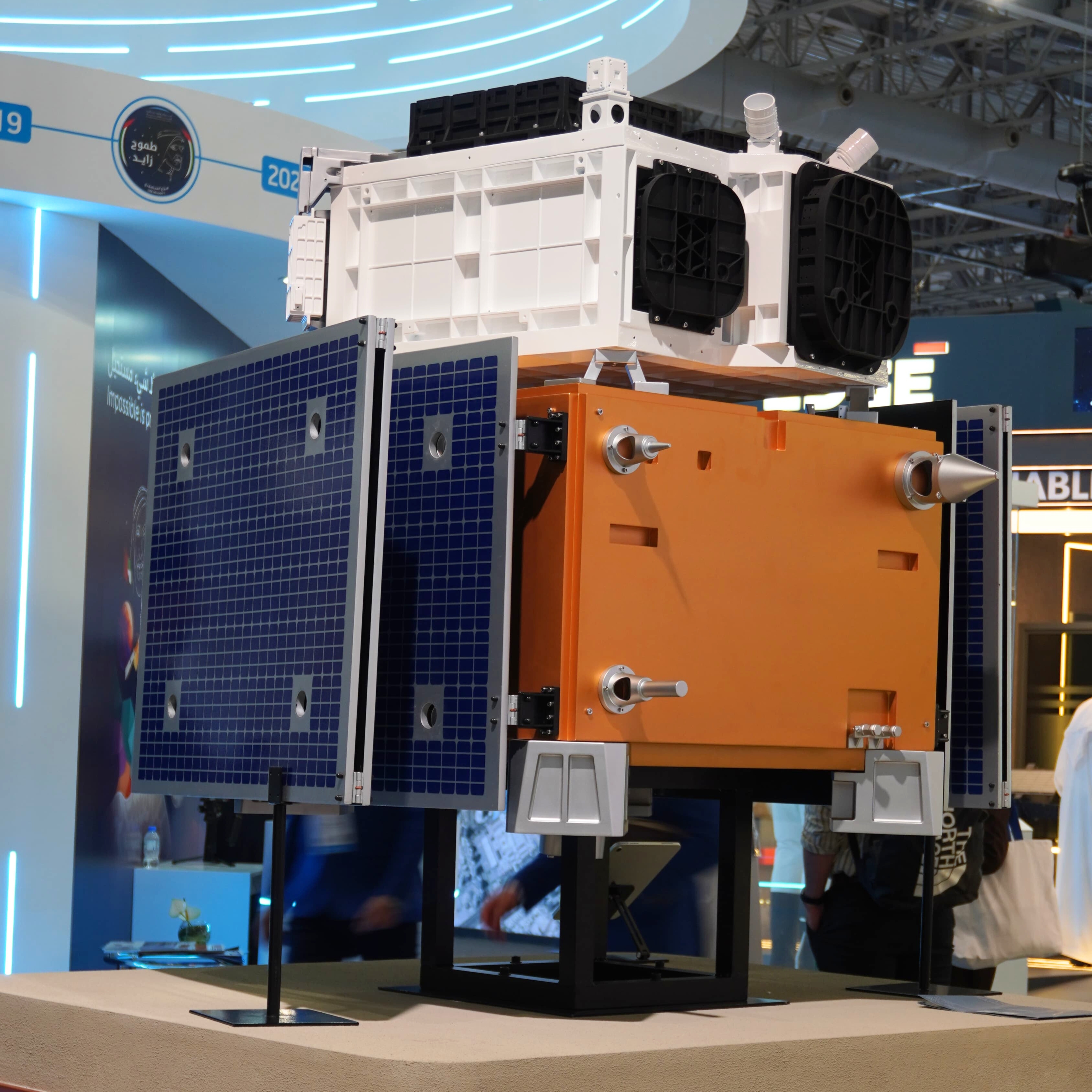

Delivering premium display models services, tailored precisely to your ideas.

Read more

Styrofoam, GRP & FRP solutions for lightweight, durable, and creative builds—made to shape bold ideas.

Read moreExplore innovations with advanced 3D printing and bespoke engineering solutions. Trusted across aerospace, medical, and tech sectors, our award-winning designs deliver unmatched precision and efficiency.

.jpg)

Ultratec 3D specializes in creating detailed architectural models that bring your vision to life. Using cutting-edge 3D printing technology, we capture every detail with precision, allowing architects and real estate developers to showcase their designs with stunning realism.

Builds objects layer by layer using thermoplastic material.

Uses liquid resin cured by UV light for detailed prints.

Sinters powdered material with a laser for durable parts.

Creates full-color objects with powdered polymers and binders.

Uses a focused laser beam to etch detailed designs.

MJF selectively fuses powdered polymers for high-precision parts.

We’ve successfully delivered innovative solutions for numerous high profile projects, showcasing our expertise in 3D printing and engineering. Our work continues to make an impact across various industries, setting new standards for quality and creativity.

Years Experience

Projects

Printers

Employees

We partner with a diverse range of industries, offering innovative 3D printing and engineering solutions tailored to their unique needs. Our clients rely on us for unmatched quality and precision in every project.

From seamless collaboration to exceptional results, they trust us to bring their ideas to life with cutting-edge 3D printing and engineering technologies. Here's what some of them have to say about their experience working with us.

Ultratec 3D provides high-quality 3D printing, prototyping, design services, and production parts for various industries including healthcare, automotive, architecture, and consumer products.

You can upload your 3D model directly through our website or contact us with your project details. We’ll respond with pricing and lead time.

We offer a wide range of materials including PLA, ABS, PETG, TPU, nylon, carbon fiber composites, and various engineering-grade resins and metals.

Yes, you can request changes before production begins. Once printing has started, changes may not be possible or may incur additional costs.

We serve a variety of industries including medical, aerospace, automotive, architecture, consumer goods, education, and manufacturing.

Discover the latest in 3D printing, rapid prototyping, and advanced manufacturing.

Any question or remarks? Just write us a message!

Say something to start a live chat!