Beyond Prototypes: How the UAE is Embracing High-Volume 3D Printing for Production

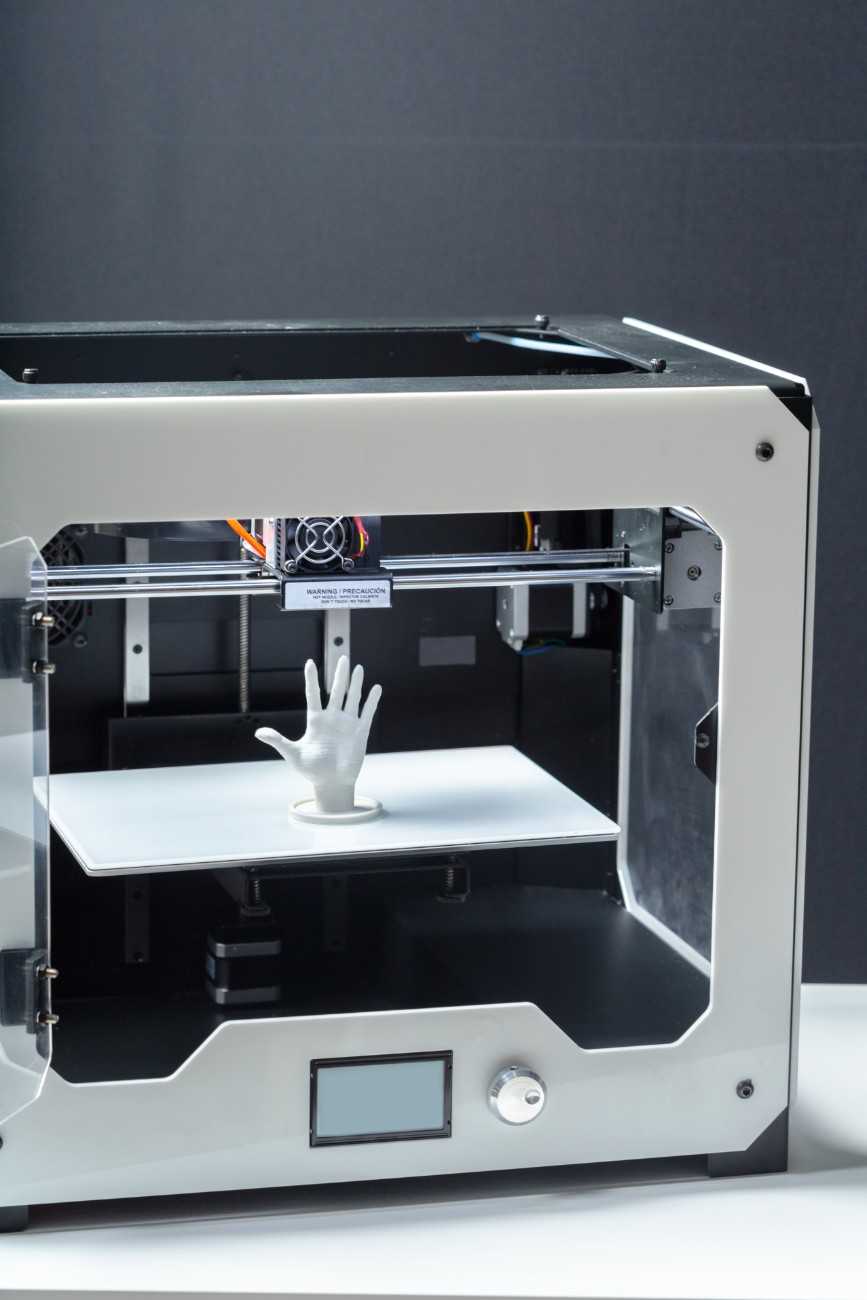

For years, 3D printing was synonymous with one-off prototypes. But the technology has evolved. Today, businesses across the UAE are leveraging industrial additive manufacturing for a far more ambitious goal: high-volume production of end-use parts. This shift from prototyping to manufacturing is transforming supply chains, enabling innovation, and creating a powerful competitive advantage.

If your business is still only thinking about 3D printing for models and mock-ups, you're missing out on its most powerful application. Here’s how you can make the leap.

The Technology Driving the Change: HP Multi Jet Fusion (MJF)

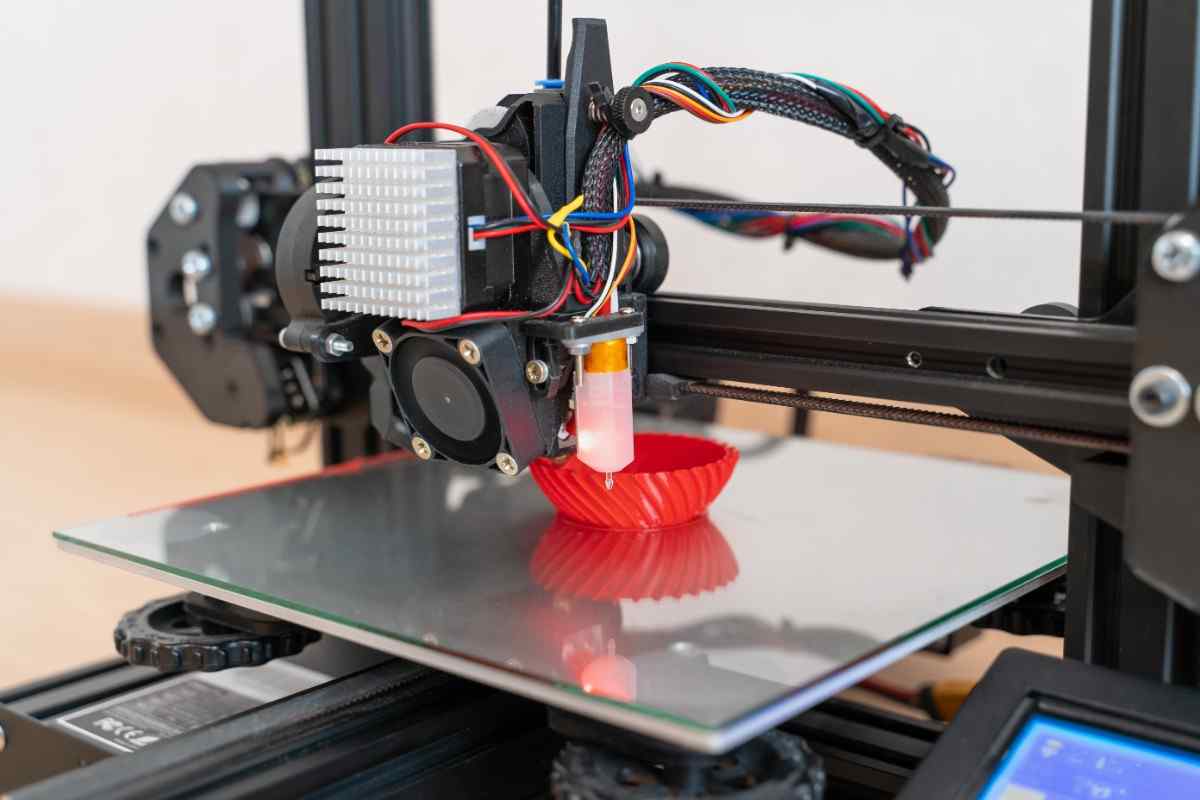

The primary catalyst for this shift is technology like HP Multi Jet Fusion (MJF). Unlike traditional layer-by-layer FDM printers, MJF is a powder-bed fusion process designed for speed, efficiency, and production-grade quality.

Key Advantages of MJF for Production:

- Speed at Scale: MJF can print an entire build chamber of nested parts in a matter of hours. This means producing hundreds of complex parts is just as fast as producing a few.

- Isotropic Strength: MJF parts have near-uniform mechanical properties in all directions, making them significantly stronger and more reliable than parts from other polymer printing methods.

- Cost-Effective at Volume: With no need for support structures and the ability to nest parts tightly, MJF minimizes waste and maximizes throughput, making it highly economical for medium to high-volume runs.

- End-Use Material: The standard material, Nylon PA12, is a robust engineering thermoplastic with excellent chemical resistance and durability, perfect for functional components.

From a Single Part to a Digital Inventory

Moving to production 3D printing means adopting a new manufacturing mindset. Instead of ordering thousands of parts from overseas and holding them in a warehouse, you can create a 'digital inventory.'

With a digital file and a trusted local production partner in the UAE, you can manufacture parts on-demand. This on-demand manufacturing model offers incredible agility:

- No Tooling Costs: Skip the massive upfront investment in injection molds. This is a game-changer for startups and for products with shorter life cycles.

- Instant Design Iteration: Need to improve a part? Simply update the CAD file and print the new version immediately. No need to scrap obsolete inventory.

- Supply Chain Resilience: By manufacturing locally in the UAE, you eliminate international shipping risks, customs delays, and supply chain disruptions.

How to Prepare for High-Volume 3D Printing

- Partner with an Expert: Choose a service provider in the UAE that specializes in production-level technologies like MJF. They should have a fleet of machines to handle demand and offer expert DfAM (Design for Additive Manufacturing) guidance.

- Optimize Your Design: While MJF is forgiving, optimizing your design for the process can further reduce material use and improve part performance. An expert partner can help you with this.

- Think in Batches: Plan your production runs in batches to maximize the efficiency of the build chamber and streamline post-processing.

Your Partner for Scalable Manufacturing in the UAE

Ultratec 3D is at the forefront of high-volume 3d printing in the UAE. Our state-of-the-art facility is equipped with a fleet of HP Multi Jet Fusion 5200 printers, specifically designed for scalable production. We partner with businesses to help them transition seamlessly from prototyping to full-scale, on-demand manufacturing.

Ready to scale your production? Contact our engineering team to discuss your high-volume project today.