3D Printing Revolutionizing Manufacturing in the Middle East

Introduction

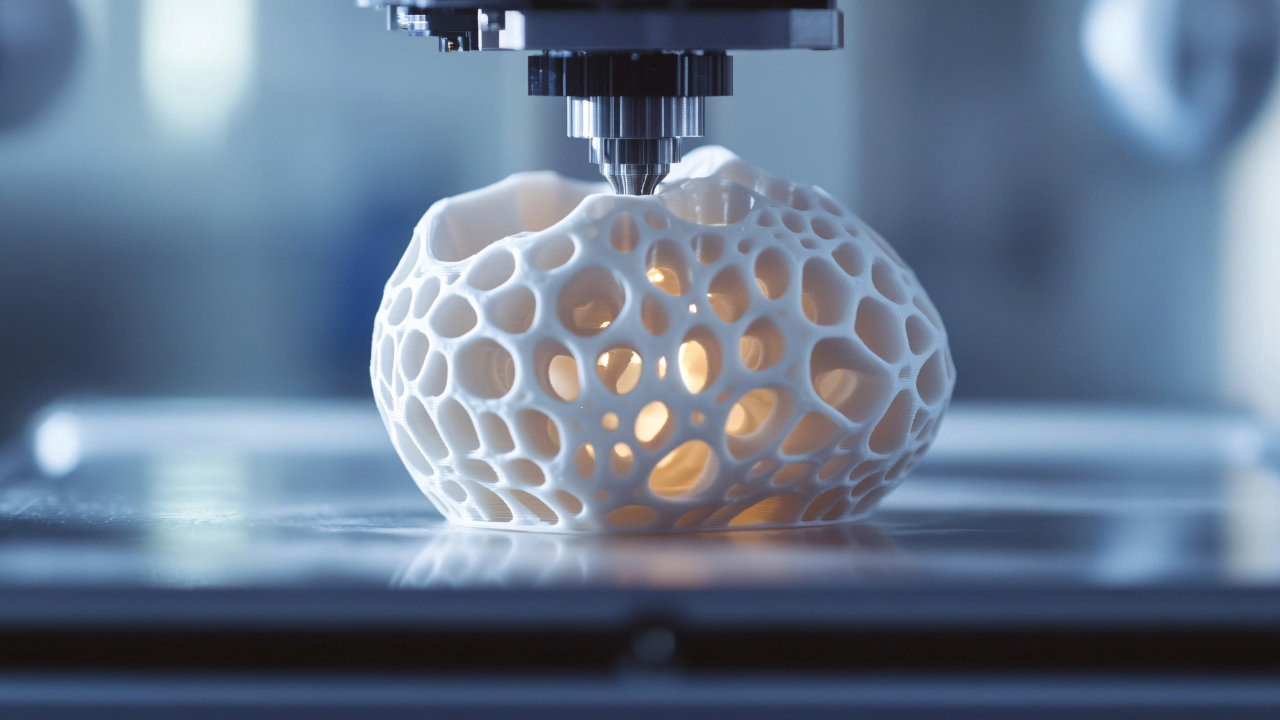

In recent years, the Middle East has been experiencing a significant shift towards embracing cutting-edge technologies to enhance efficiency and sustainability across various industries. One such technology that has been gaining momentum in the region is 3D printing, also known as additive manufacturing. Companies like Ultratec 3D Printing in the UAE and Saudi Arabia are at the forefront of this revolution, offering top-notch services to cater to the evolving needs of businesses.

The Benefits of 3D Printing

Cost-Effectiveness

3D printing has revolutionized traditional manufacturing processes by significantly reducing production costs. With additive manufacturing, companies can create complex designs with fewer materials, minimizing waste and ultimately cutting down on expenses. This cost-effectiveness is particularly appealing to businesses looking to streamline their operations without compromising on quality.

Enhanced Efficiency

Another key advantage of 3D printing is its ability to streamline the manufacturing process. Traditional manufacturing techniques often involve multiple steps, tools, and machinery. In contrast, additive manufacturing simplifies the production process by directly building components layer by layer from digital designs. This not only saves time but also enhances overall operational efficiency.

Sustainable Practices

In an era where sustainability is paramount, 3D printing offers a more eco-friendly alternative to traditional manufacturing methods. By producing items on-demand and using recyclable materials, businesses can significantly reduce their carbon footprint. This shift towards sustainability not only benefits the environment but also resonates with consumers who prioritize eco-conscious companies.

Ultratec 3D Printing: Pioneering Innovation

Ultratec 3D Printing is a leading provider of 3D printing and engineering services in the UAE and Saudi Arabia. Their cutting-edge solutions cater to a wide range of industries, including aerospace, automotive, healthcare, and more. Through services such as additive manufacturing, product development, and mechatronics engineering, Ultratec is empowering businesses to embrace the future of manufacturing.

Key Takeaways

Cost-Efficiency: 3D printing reduces production costs by minimizing waste and optimizing material usage.

Efficiency: Additive manufacturing simplifies the production process, saving time and enhancing operational efficiency.

Sustainability: By using recyclable materials and on-demand production, 3D printing promotes eco-friendly practices.

Embracing 3D printing is not just a technological advancement but a strategic decision to stay ahead in a rapidly evolving market. As companies in the Middle East continue to adopt additive manufacturing, the region is poised to become a hub for innovation, efficiency, and sustainability in the manufacturing sector.