High-Resolution Industrial Precision

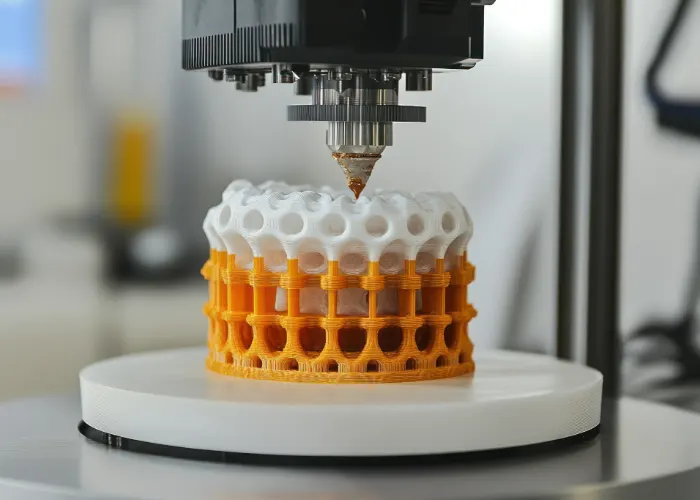

Ultratec 3D leverages advanced FDM technology to deliver precise and durable prototypes and parts. Our solutions ensure high quality and efficiency for industrial applications.

Ultratec 3D's FDM technology offers reliable and cost-effective 3D printing solutions. Ideal for rapid prototyping and small-scale production, FDM is perfect for a wide range of industrial applications.

Ultratec 3D leverages advanced FDM technology to deliver precise and durable prototypes and parts. Our solutions ensure high quality and efficiency for industrial applications.

Our FDM technology combines rapid production with consistent precision, making it ideal for producing functional prototypes and small production runs.

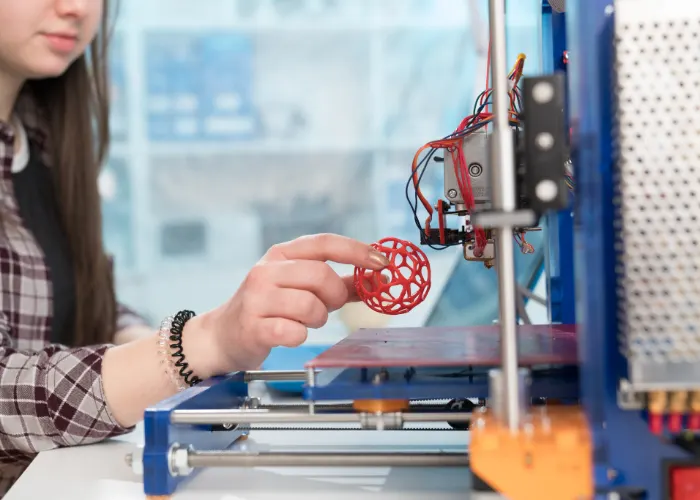

Produce affordable prototypes with FDM technology, allowing for rapid iteration and design validation.

FDM supports a variety of thermoplastic materials, enabling diverse applications from flexible to rigid parts.

FDM offers quick turnaround times and is ideal for producing functional parts and small production runs.

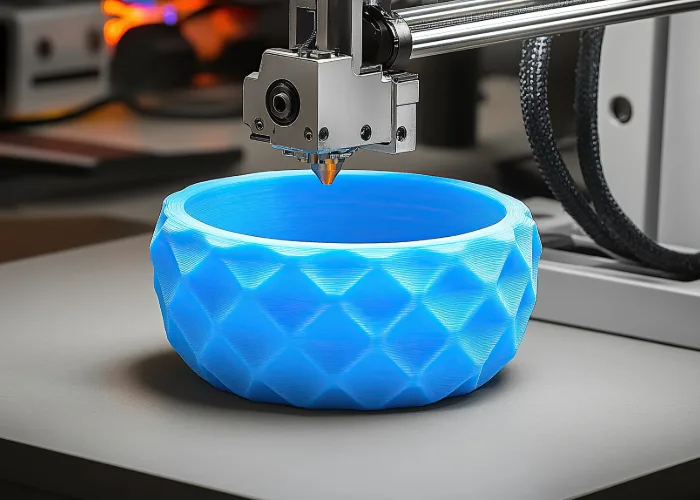

Learn how FDM technology is revolutionizing rapid prototyping and production with its cost-effective and versatile approach.

Read More

Discover the benefits of FDM technology in product design, offering reliable and efficient production of durable parts.

Read More

An in-depth comparison of FDM versus SLA, SLS, and MJF, focusing on cost, efficiency, and application suitability.

Read More

Explore how FDM technology is being applied across industries such as automotive, aerospace, and consumer goods.

Read MoreHave questions about our 3D printing technologies? Find answers below.